Description

Calibration Block for use with Full Matrix Capture (FMC) and TFM (Total Focusing Method). FMC is a data acquisition process used to collect ultrasonic data. The matrix of signals can be stored for later processing. TFM is a signal processing algorithm that makes use of FMC data to focus an ultrasonic image at all points, displaying the optimal resolution everywhere. This allows for very accurate defect characterization, making the method useful for any ultrasonic application where characterization and sizing are critical.

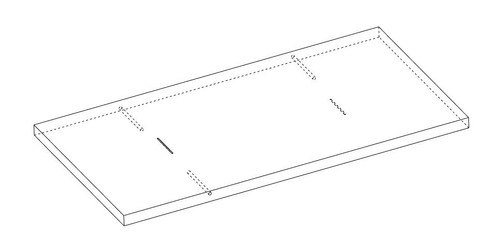

PH Tool's FMC Calibration Block is used for establishment of primary reference responses for FMC/TFM enabled systems. Block contains two side-drilled holes at 1.5 deep minimum at 1/8 diameter. The holes are separated, center-to-center, by twice their diameter, straddling the block centerline. A through-wall slot at the center of the block shows a vertical response from the top to the bottom of the plate. A machined notch measuring 11%T max. deep x 0.040 wide x 1.0 long min is also included on the block. Welded handles included for lifting. In accordance with ASME Sec V, 2019 version.

ASME Calibration Blocks are intended to be representative of actual components, and therefore do not have the smooth scanning surfaces found on most general-purpose test blocks like the IIW or DSC. Instead, our ASME Calibration Blocks are media blasted on all surfaces to create a rough surface texture that is more characteristic of real-world inspection conditions.

- Thickness: Over 1 thru 2 thick (please specify exact thickness needed) - These blocks cover weld thicknesses ±25% their own thickness

- Overall Size: 7.5 wide x 13 long

- Weight: up to 42 lbs. (depending on thickness)

- Supplied with welded handles for transport

- Material: A516-70 Steel, bare