Description

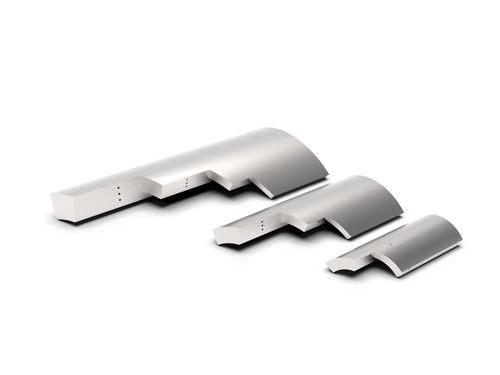

Jointly designed by PH Tool and Holloway NDT, a set of three Extended Range Variable Wall (ERVW) Piping Calibration Blocks with Side-drilled Holes has been developed for calibrations in the axial direction for examination of circumferential butt welds. Three conveniently-sized and lightweight blocks cover a wide range of inspection sizes on the pipe schedule chart that would otherwise require a large number of conventional piping calibration blocks. ERVW Blocks are officially covered under US Patent No. US D881,728 S, dated April 21, 2020.

Design and development of the new blocks was performed concurrently with simulations using CIVA software. The basic design remains compliant with ASME Sec V Article 4, Fig. T-434.3-2 requirements, but with modifications including varying thickness steps on a single block, and reconfigured reference reflector locations to optimize size and functionality. The majority of piping examinations are performed on circumferential welds. As a result, the reflectors included on these blocks are oriented in the circumferential direction, for calibration in the axial direction. Side-drilled Holes were selected as the reference reflector type based on enhanced sensitivity vs. notches at a variety of angles, making them ideal for PAUT calibrations.

The blocks have a consistent outside diameter, while providing varying thickness steps on the inside diameter. The OD of each block is machined to span the maximum number of pipe sizes based on ASME criteria. ID thickness steps were customized to span the range of standard pipe schedules. The steps were placed on the ID rather than the OD to maximize usefulness of wedge curvature as per the requirements of T-432.2 introduced in 2017.

Blocks used for establishing DAC/TCG calibrations must provide suitable length and strategically placed reference reflectors to avoid conflicting echoes. The dreaded “split-DAC” is often required on shorter blocks which may result in sudden steps up/down in the TCG curve. To establish uninterrupted DAC/TCG curves, the segment lengths and reflector positions were modeled to control interfering reflections. Also, block ends were tapered to deflect termination echoes.

Set Details:

• Small Block (3-5”) is 7 inches long, and weighs 2.8 lbs.

• Medium Block (6-10”) is 10 inches long, and weighs 7 lbs.

• Large Block (12-20”) is 16 inches long, and weighs 20 lbs.

• Surface Finish: Media-blasted to 125 Ra to simulate inspection conditions

• Materials: Most commonly requested in carbon or stainless steel, but other alloys available upon request

• Machine-engraved transducer positioning marks to aid in functionality and maximize signal from SDHs

• Machine-engraved identification text (including unique serial no.)

• Inspection pipe sizes covered by each thickness step also machine-engraved on OD.